Many businesses and online businesses find they are unable to compete in the market due to the absence of a defined supply chain strategy. If you think you are in this situation, don’t panic—it can be corrected with some dedicated effort. In this guide, we will walk you through the necessary steps to create a robust supply chain strategy so that you will be able to meet your clients’ needs effectively and efficiently.

Step 1: Understand your customers’ needs

- Are you sure you know what your customers want? The key to good sales is highlighting the benefits that your product or service brings to your customers. However, you will be shocked once you find out how many businesses are unaware of their customers’ real needs. The easiest way to find out what customers need is asking directly. By talking to your customers, you will have a precise understanding of which challenges they face when buying or looking for products, so that you can offer real beneficial solutions. Also, this will help you assess whether a single logistics strategy is sufficient or whether you need different logistics strategies for different customer segments. For example, if you have an ecommerce that sells clothing, you might have to focus more on flexible and simple return policies.

Also having a clear understanding of your customers is equally important in defining your strategy.

Key customer aspects to explore:

- Who customers are

- What customers do

- Why customers buy

- When customers buy

- How customers buy

- What makes customers feel good about buying

- Customers’ opinion about you

- Customers’ opinion about your competitors

Key areas of your business to explore:

- Packaging and labelling

- Delivery service levels

- Warehouses and proximity

- Reverse logistics

- Delivery frequency

- Delivery time windows

- Inventory levels

Step 2: Conduct a gap analysis

- Are you aware of how your current business set-up measures up against customer expectations and industry trends? Perform a gap analysis to identify performance gaps and where improvement in your processes is required.

Step 3: Benchmarking

- How does your supply chain performance compare to key players in your industry? This is very important to understand what you can offer as an extra and how you can distinguish your business in the market.

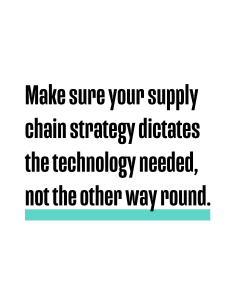

Step 4: Integrate adequate technology

- What technology will you need to support your new strategy? Evaluate your needs to identify which supply chain software solutions can help you meet expectations more efficiently, such as WMS, inventory optimization software, TMS, forecasting systems, and so on. Make sure your strategy dictates the technology needed, not the other way round. A very common mistake among businesses is trying to make a new strategy fit the capabilities of the technological solutions they already have.

For example, a fashion ecommerce company decides to develop a new supply chain strategy aimed at enhancing customer experience by offering faster order fulfillment. However, they only rely on outdated systems that don’t support real-time visibility and lack automation. Without investing in new advanced solutions with these features to support the defined goals, achieving faster order fulfillment will be impossible.

Step 5: Enhance visibility into operations and performance

- Which technology solutions can enhance your performance and visibility?

Your business must be equipped with the right tools to meet your strategy’s demand. If you are experiencing fluctuating demand, high error rates, inventory management challenges, low fulfilment speed and warehouse space issues, it’s time to implement automation in your warehouse, like inventory tracking systems, and other technology-assisted processes.

Step 6: Risk assessment

- Are you aware of the risks associated with your supply chain? A critical step in strategy development is evaluating risks on supply and demand sides of the chain, as well as internal operations. The purpose is to spot problems and act to address them, thus reducing the likelihood of their occurrence, prevent negative impacts, and protect your business.

Step 8: Define and measure the new strategy and its objectives

- Is your new supply chain strategy clear and measurable? Ensure your objectives are SMART (Specific, Measurable, Achievable, Realistic, Time-bound) and make sure everything is documented clearly. To monitor and measure the success of your strategy define relevant and manageable KPIs, which will offer clear insights into your business performance without causing analysis paralysis. Also, make sure you integrate the technology capable of gaining and storing information needed for KPI tracking.

For example, if you want to improve your order fulfillment process you should set relevant KPIs, like order accuracy, delivery time, and inventory turnover. Tracking these KPIs requires implementation of a Warehouse Management System (WMS) that provides real-time inventory tracking and analytics. This technology allows you to gather necessary information for Key Performance Indicators (KPIs) through various automated and real-time data collection methods. For instance, a WMS uses barcode scanning and RFID technology, thanks to which you can monitor accuracy in receiving, packing, picking, and shipping processes. This is the only way to make sure your data is precise and you have constant access to information regarding order processing times, inventory turnover rates, and fulfillment accuracy for comprehensive analytics and reports.

The most common mistakes in supply chain strategy

There are three major mistakes companies make when defining a supply chain strategy. Let’s discover them and find out how to avoid them.

Misalignment

The supply chain strategy must support the main objectives of the business. When these strategies diverge from the main goals, it will create plenty of room for inefficiency and confusion.

Key points:

- Assess your business’ main objectives.

- Ensure your supply chain strategy is apt to support these goals.

- Constantly review and adjust the strategy to stay aligned with any changes.

Don’t set too many objectives

Another common error business owners make is setting too many objectives in the supply chain strategy. Your direction should be clear and focused. Normally, when too many objectives are set, it is easy to diverge from goals and lose track.

Pro Tips:

- Limit objectives to three or four key areas and make sure they are clear.

- Focus on essentials, like cost, service availability, quality, and safety.

Limit your KPIs

Having too many Key Performance Indicators (KPIs) can easily lead to analysis paralysis. Your aim must be turning data into information and information into useful insights. This is why KPIs should be meaningful and manageable; having a comprehensive and clear view of what is going on avoids causing confusion when monitoring performance.

Pro Tips:

- Align KPIs with your main objectives, technology, operations, and staff.

- Aim for a manageable number of KPIs, like 9 or 10 (one for every enabler if you have three enablers per objective).

- Keep KPIs relevant and focused to ensure they provide actionable insights.