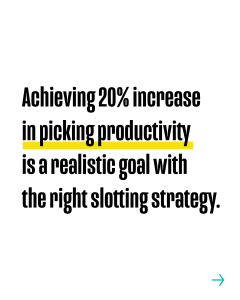

How does a 20% increase in picking productivity sound? Yes, believe us, there’s always room for improvement in your warehouse. This is why we have decided to share a useful guide for ecommerce owners, explaining how effective warehouse slotting is beneficial for more accurate and faster picking processes, ultimately impacting order fulfillment and sales. Let’s discover more about effective product slotting and which opportunities it uncovers for your business!

What is product slotting?

Simple in theory but complex in practice, product slotting means assigning SKUS to specific locations in the warehouse. To achieve optimal results, this process must be supported by a well-planned project and adhere to specific criteria. The aim is to organise how products are stored to optimise warehouse available space and reduce staff travel time. Picking is indeed the most time-consuming warehouse process and constitutes 50%, or even more, of total working hours. So, improving this aspect will impact your fulfillment times directly. But this is not the only advantage.

Benefits of slotting in your warehouse

You may be thinking: “Is reorganising my whole warehouse worth the hassle?”. Even though it is a challenging task, and it’s tempting to store inventory randomly in any available space, this absence of method is short-sighted and creates a series of disruptions. Slotting is, in fact, not merely about making your warehouse aesthetically tidy. A well-planned slotting project typically uncovers opportunities to increase warehouse space. Often, after slotting, supposedly full warehouses reveal a lot of unused space sufficient for warehouse expansion. Also, achieving 20% increase in picking productivity is a realistic goal with the right slotting strategy in place. Even though the most significant impact of slotting is, as already mentioned, on picking operations and space optimisation, you will find that it creates a positive domino effect on various other aspects of warehouse management.

Increase in storage capacity

Slotting can uncover additional storage space, accommodating scalability and avoiding using the warehouse at full capacity, which can become an obstacle for successful fulfillment operations. Having enough space to work creates less chance of error and increases speed of operations. This ensures warehouses can manage larger order volumes without major increases in labour or fulfillment expenses.

Increase in safety for your team and products

Your staff will be able to operate in a safer working environment. Same goes for the products you store; if they are well organised and kept they won’t risk being damaged or getting lost.

Increase in fulfillment times

Simply put, if items are picked faster, your orders will be processed faster.

Reduction of warehouse expenses

After optimizing space and processes, you will experience a significant lowering of carrying costs, including storage, cost of picking, and putaway.

You can use the following formula to calculate your current carrying costs:

Inventory carrying cost = Storage costs + Employee salaries + Opportunity costs + Depreciation costs / Total value of annual inventory

Best practices for slotting

Especially if you have a diverse product range and you deal with large volumes of products, there are different tactics you can adopt for effective slotting.

Special storage

Handling products with special storage requirements, like high value items or temperature-sensitive products, is relatively straightforward, as in most cases, you will group such products together in a dedicated area. Obviously, if your ecommerce only sells these products, your entire warehouse will be structured to handle these products in a dedicated environment.

Grouping product families

If your inventory has a mix of items that sell sporadically and others that are frequently ordered together, you can organise the latter in adjacent slots to accelerate the picking process.

Slotting by velocity

Slotting by velocity means prioritising frequency rather than sales volume. This means you must place products that are picked frequently closest to the dispatch zone of the warehouse. But what if you have many fast-moving products? Placing them all close to the dispatch-zone could cause congestion. In this case, consider using another metric to orient yourself on which to prioritise or spread fast-moving items across the warehouse in accessible areas.

But as all things, it’s never all black and white. In fact, there may be conflicting goals, such as slotting by sales velocity versus organising by product groups. Fortunately, product families often have similar sales velocities but sometimes you’re forced to compromise, develop a hybrid approach, or use a WMS to suggest optimal slotting.

Predicting velocity

The general slotting rule is that fast-moving SKUs should be easily accessible, while slow-moving ones must be out of the way.

Most warehouse managers use ABC analysis to understand SKU velocity. This method involves analysing order frequency of each SKU over a specific period, usually 1 month. After, the SKUS are categorised based on their order volume:

- A items placed in most accessible locations: top 50% of ordered SKUs.

- B items in between: next 25%.

- C items in between: remaining 25%.

- D items in least accessible areas: SKUs that were not ordered during the period.

Instead relying just on historical data, modern Warehouse Management Systems (WMS) use predictive analytics to forecast demand, monitor surges in demand, seasonality, and market trends. This allows managers to understand SKU velocity changes in advance and make slotting arrangements proactively.

Data is the answer

How can you ensure your slotting strategy is constantly optimised? The answer lies in leveraging the right technology. Warehouse product slotting is a data-driven activity and requires a lot of data. So the most important thing to do is make sure you have access to the data necessary to make relevant slotting calculations. To implement a smart and efficient warehouse slotting calculation process, having an advanced Warehouse Management System (WMS) is essential.

Inventory data required for slotting should include:

- SKU picking methodology

- Number of pallets, cartons and broken case eaches of each SKU

- SKU hits (the number of times a product is picked)

- SKU numbers and descriptions

- Pick quantities (SKUs picked per order)

- SKUs picking trends

- SKU sizes and weights

- Total SKU quantity, reorder point and reorder quantity

- Demand trends.

eLogy’s advanced WMS is designed to help you manage your inventory in real time, automating data collection and analysis. Whether you have your own warehouse or want to take advantage of our comprehensive ecosystem for ecommerce, by integrating eLogy’s WMS, you can monitor inventory levels, track product locations, and adjust slotting plans dynamically to respond to customer demand. With real-time data and intelligent insights, eLogy’s WMS empowers you to make smarter decisions, encouraging a data-driven approach to warehouse management.